This long weekend is full of little tasks. Besides a little volunteering at the Westcoast Curling Classic, I did a bunch of tasks that are the opposite of Spring Cleaning: harvesting plants, putting compost on the garden, and putting away the potting soil in the deck pots that produced so many tomatoes and peppers this year.

Part of that last task is separating the soil from the drain rock I use at the bottom of the pots. It got me thinking about how our veggie plants are benefiting from our education. More directly that you might expect: my drain rocks are mostly rock samples collected during thesis work by me, or by my better half.

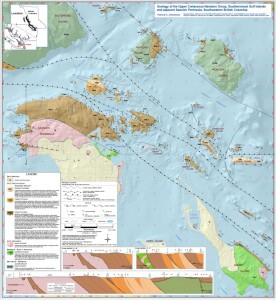

My Master’s thesis was a pretty old-school map-the-geology type thing. I spent probably the most idyllic summer fieldwork season even mapping a bunch of little islands off the east costs of the Saanich Peninsula, and a bit of the Peninsula itself. You can read the abstract here , or even download the entire 260MB bastard in pdf. I would highly recommend against that, unless you find ichnofacies analysis to be compelling, but it does include a lot of pretty diagrams I drew myself!

|

| Three years of my life: zoom to enrage. |

During the summer, I collected a lot of rock samples. Some to serve are representative hand samples for future comparison, some to cut into thin sections to do petrology, some because they contained fossils (my not being a palaeontologist, I need to look them up or ask someone smarter than me to identify them); and some just because they looked cool.

The Smart One in the Family had a different type of thesis. She was up in the interior of BC looking at glacial deposits, and trying to decipher patterns in the deposits to figure out which way the ice flowed at what time, and concomitant to that, where gold or other lucrative minerals might be found under the glacial deposits based on evidence smeared out within the surface deposits.

Aspects of her thesis relied on statistics to tease trends out of seemingly random data. To do that, you generally need to start with a lot of very meticulously collected data. One line of evidence she used for ice flow was collecting samples of pebbles from glacial till, and characterising the pebble types to see if there are patterns across space. To have adequate statistical support, she needed to collect 100 samples (using a randomising selection method) from each site. To provide adequate statistical control over these sites, she needed 100 sites. So she collected, and petrologically described, 10,000 pebbles. Compared to my couple of buckets of samples, this was a monumental task, and it was only one aspect of her thesis. It is clear which of us is the geologic stud.

So what to do with 10,000 pebble-sized samples, and thousands of others, once your thesis is done?

A few years after her defence, I took a couple of 20L pails of pebbles and mud samples (used for geochemical analysis) that were kicking around a lab at SFU and dropped them in a persistent pothole puddle on the North Road Trail on Burnaby Mountain – every time I ride my mountain bike around that (to this day, puddle-free) corner, I think about the rocks there, and what an enterprising geologist would make of all these Adams Plateau pebbles on Burnaby Mountain.

Some of my samples were pretty enough that they are around my garden today. Some of her samples were used to make patio tiles by her Mom, as part of a family-themed patio paving project.

However, a combined ~17 years after our thesis defences, we still have a few 20-L buckets of pebbles, samples, off-cuts, and fossil samples kicking about. Averse to throwing things out (much to her chagrin), I am always trying to find uses for them… This is how the drainage rocks in our veggie pots came from the Gulf Islands and the Adams Plateau. I think this makes them cooler than a $4.99 bag of crushed quartzite drainage rock I could buy from Home Depot. Especially when I find a nice polished piece of sandstone with a Sharpie-lettered sample number on it. Memories of that summer in the bottom of my veggie pots.. oh, look, there is good ol’ sample PDJ04-107a. That was a nice spot.